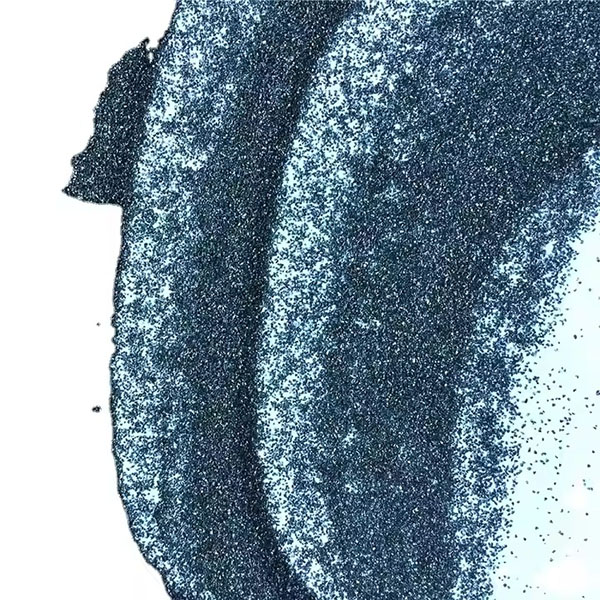

Black silicon carbide is made from quartz sand and smokeless acetylene as the main raw material. It is made via light resistance from hydro metallurgical, it is black opaque body hexagonal crystal and MOHS-hardness the 9.15, which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat.

Black silicon carbide is higher toughness than green silicon carbide with sic purity 98%, it have been used for processing glass, ceramic, stone, refractory materials, cast iron and other metal.

The physical and chemical analysis

Used for abrasive, blasting, grinding. | |||

Properties type | 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#. | ||

Guarantee Value | Typical Value | ||

Chemical composition | SIC | 98.0 min | 98.5 |

F.C | 0.2 max | 0.1 | |

Fe2O3 | 0.2 max | 0.15 | |

H2O | 1.0max | 0.30 | |