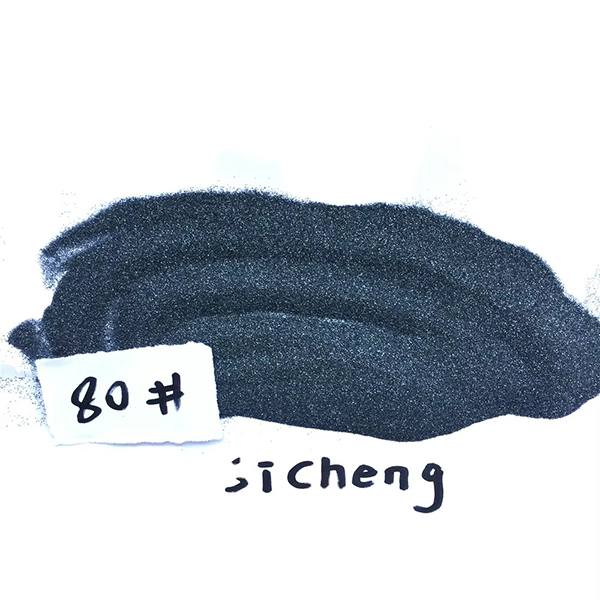

Black Silicon carbide Grain is an extremely hard and 98% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, surface treatment, grinding on hard material such as marble, glass, jade, etc.

Black silicon carbide Specification:

| TYPICAL CHEMICAL ANALYSIS | TYPICAL PHISICAL PROPERTIES | ||

| SiC | ≥98% | Hardness: | Mohs:9.15 |

| SiO2 | ≤1% | Melting Point: | Sublimes at 2250 ℃ |

| H2O3 | ≤0.5% | Maximum service temperature: | 1900℃ |

| Fe2O3 | ≤0.3% | Specific Gravity: | 3.2-3.45 g/cm3 |

| F.C | ≤0.3% | Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Magnetic content | ≤0.02% | Color: | Black |

| Particle shape: | Hexagonal | ||

Size Distribution of black silicon carbide:

| Grit | 1 | 2 | 3 | 3 and 4 | 5 | Q5max,% | ||||

| W1,um | Q1,% | W2,um | Q2max,% | W3,um | Q3min,% | W4,um | Q3+Q4min,% | W5,um | ||

| F8 | 4000 | 0 | 2800 | 20 | 2360 | 45 | 2000 | 70 | 1700 | 3 |

| F10 | 3350 | 0 | 2360 | 20 | 2000 | 45 | 1700 | 70 | 1400 | 3 |

| F12 | 2800 | 0 | 2000 | 20 | 1700 | 45 | 1400 | 70 | 1180 | 3 |

| F14 | 2360 | 0 | 1700 | 20 | 1400 | 45 | 1180 | 70 | 1000 | 3 |

| F16 | 2000 | 0 | 1400 | 20 | 1180 | 45 | 1000 | 70 | 850 | 3 |

| F20 | 1700 | 0 | 1180 | 20 | 1000 | 45 | 850 | 65 | 710 | 3 |

| F24 | 1180 | 0 | 850 | 25 | 710 | 45 | 600 | 65 | 500 | 3 |

| F30 | 1000 | 0 | 710 | 25 | 600 | 45 | 500 | 65 | 425 | 3 |

| F36 | 850 | 0 | 600 | 25 | 500 | 45 | 425 | 65 | 355 | 3 |

| F40 | 710 | 0 | 500 | 30 | 425 | 40 | 355 | 65 | 300 | 3 |

| F46 | 600 | 0 | 425 | 30 | 355 | 40 | 300 | 65 | 250 | 3 |

| F54 | 500 | 0 | 355 | 30 | 300 | 40 | 250 | 65 | 212 | 3 |

| F60 | 425 | 0 | 300 | 30 | 250 | 40 | 212 | 65 | 180 | 3 |

| F70 | 355 | 0 | 250 | 25 | 212 | 40 | 180 | 65 | 150 | 3 |

| F80 | 300 | 0 | 212 | 25 | 180 | 40 | 150 | 65 | 125 | 3 |

| F90 | 250 | 0 | 180 | 20 | 150 | 40 | 125 | 65 | 106 | 3 |

| F100 | 212 | 0 | 150 | 20 | 125 | 40 | 106 | 65 | 90 | 3 |

| F120 | 180 | 0 | 125 | 20 | 106 | 40 | 90 | 65 | 75 | 3 |

| F150 | 150 | 0 | 106 | 15 | 90 | 40 | 75 | 65 | 63 | 3 |

| F180 | 125 | 0 | 90 | 15 | 75 | * | 63 | 40 | 53 | * |

| F220 | 106 | 0 | 75 | 15 | 63 | * | 53 | 40 | 45 | * |

Application:

1 Refractory,Furnace Burden,Castable,Ramming Compoynd,Refractory Bricks etc

2 Blasting,surface Treatment,Rust Removal

3 Cusmetics products manufacturing,Beauty crafts and Dermabrasion etc

4 Ceramic products

5 Grinding wheels,sandpaper etc

6 raw material of Knife Grinder,Whetstone,oilstone,grinding stone,abrasive stones and so on

7 Used to produce Polishing wax,polishing fluid,grinding powder,grinding fluid and so on